Top 5 Oil Equipment Maintenance Services

In the dynamic world of oil and gas, maintaining equipment is crucial for operational efficiency and safety. Let's explore the five most in-demand services in oil equipment maintenance, highlighting their importance and profitability.

1. Preventive Maintenance Programs

Preventive maintenance is the cornerstone of efficient oil operations. This service involves regular inspections, cleaning, and minor repairs to prevent unexpected breakdowns. It's highly profitable due to its ability to extend equipment life and reduce costly downtime.

2. Corrosion Control and Coating Services

Corrosion is a major issue in the oil industry. Specialized coating services protect equipment from harsh environments, extending their lifespan and ensuring safety. This service is in high demand and offers substantial profit margins due to the specialized skills and materials required.

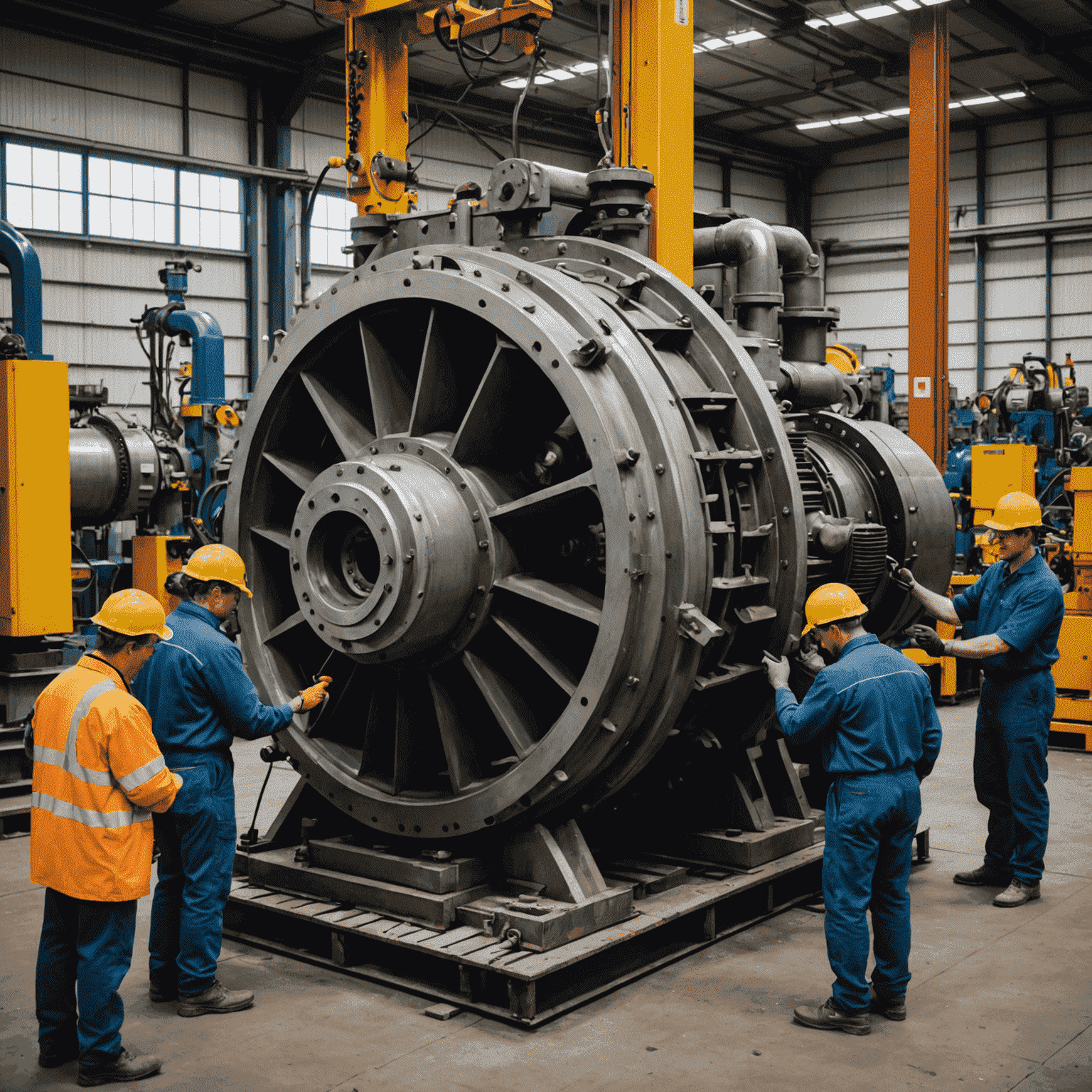

3. Pump and Compressor Overhaul

Pumps and compressors are the heart of many oil operations. Regular overhauls are essential for maintaining efficiency and preventing failures. This service is highly profitable due to the critical nature of these components and the specialized expertise required.

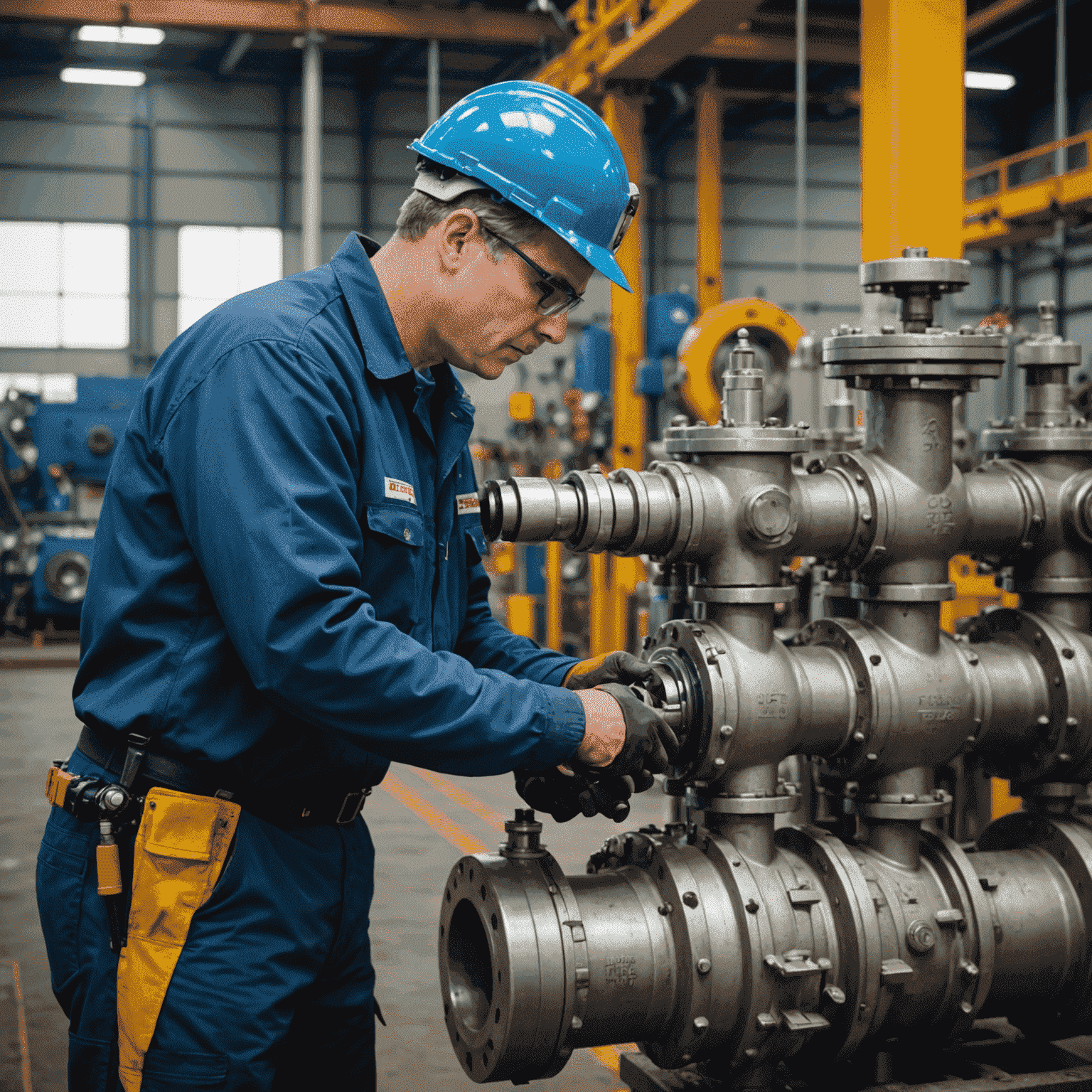

4. Valve Maintenance and Repair

Valves control the flow of oil and gas throughout the production process. Proper maintenance ensures safety and efficiency. This service is in constant demand and offers good profit margins, especially for those specializing in high-pressure or exotic material valves.

5. Instrumentation and Control System Maintenance

Modern oil facilities rely heavily on sophisticated instrumentation and control systems. Maintaining these systems requires specialized knowledge and tools, making it a highly profitable service. As technology advances, this area continues to grow in importance and demand.

Conclusion

These top five oil equipment maintenance services not only ensure the smooth operation of oil facilities but also offer significant profit potential. By focusing on these areas, maintenance service providers can tap into a lucrative market while contributing to the efficiency and safety of the oil industry. Remember, in the world of oil equipment maintenance, expertise and reliability are key to generating substantial income and building a successful business.